How Electric Cars Move

Published 2020-11-04T00:00:00Z

I've always been a fan of electric cars. They're fast, don't require a trip to the gas station, and like Earth better than their gas-powered cousins. But mostly because they are QUICK.

In your typical daily driver, you have an engine with hundreds of tiny little components moving to spin your wheels. You've got pistons pushed by explosions, valves clicking away hundreds of times per second, camshafts relying on clever tricks to squeeze more power from the gas. But in an electric car, all you've got is a big cylinder of magnets spun by electricity. There's less to go wrong in an electric vehicle because fewer components have to move to make the car drive.

THREE-PHASED POWER IS MAGICAL

AC power means that the current changes direction many times per second. You can represent this change as a sine wave between negative and positive voltage. Most home power is single-phase AC, and in the United States, the frequency of AC power is 60hz. In European countries, it's typically 50hz.

Single phased power means you have one wire come into your home. An appliance will draw power from the hot wire, use it to do work, and send current back over the neutral wire. The neutral wire and your power's source connect to the ground. Electric current must go back to the generator to complete the circuit, so they travel back to the generator through the Earth.

You might have heard of three-phased AC before: some workshops, factories, and businesses in your town might have three-phased power. What that means is three wires come into the building, each with 60hz AC power, but the phase is different between each wire. One wire is at 0 degrees, like your home power, but the other wires have phase offsets of 120 and 240 degrees. If we were to draw the voltage on each wire as a sine wave and sum them all up, we would see a flat line at 0 volts.

0 volts??? How does that work? At any given time, when one phase is supplying electricity, the other two provide a return path for power. Three-phased power results in a smoother connection that always completes the circuit instead of the awkward 60hz shuffle you get with single-phased power. You need the smoothness of three-phase electricity to operate an electric car and get good efficiency and power.

THE ENGINE

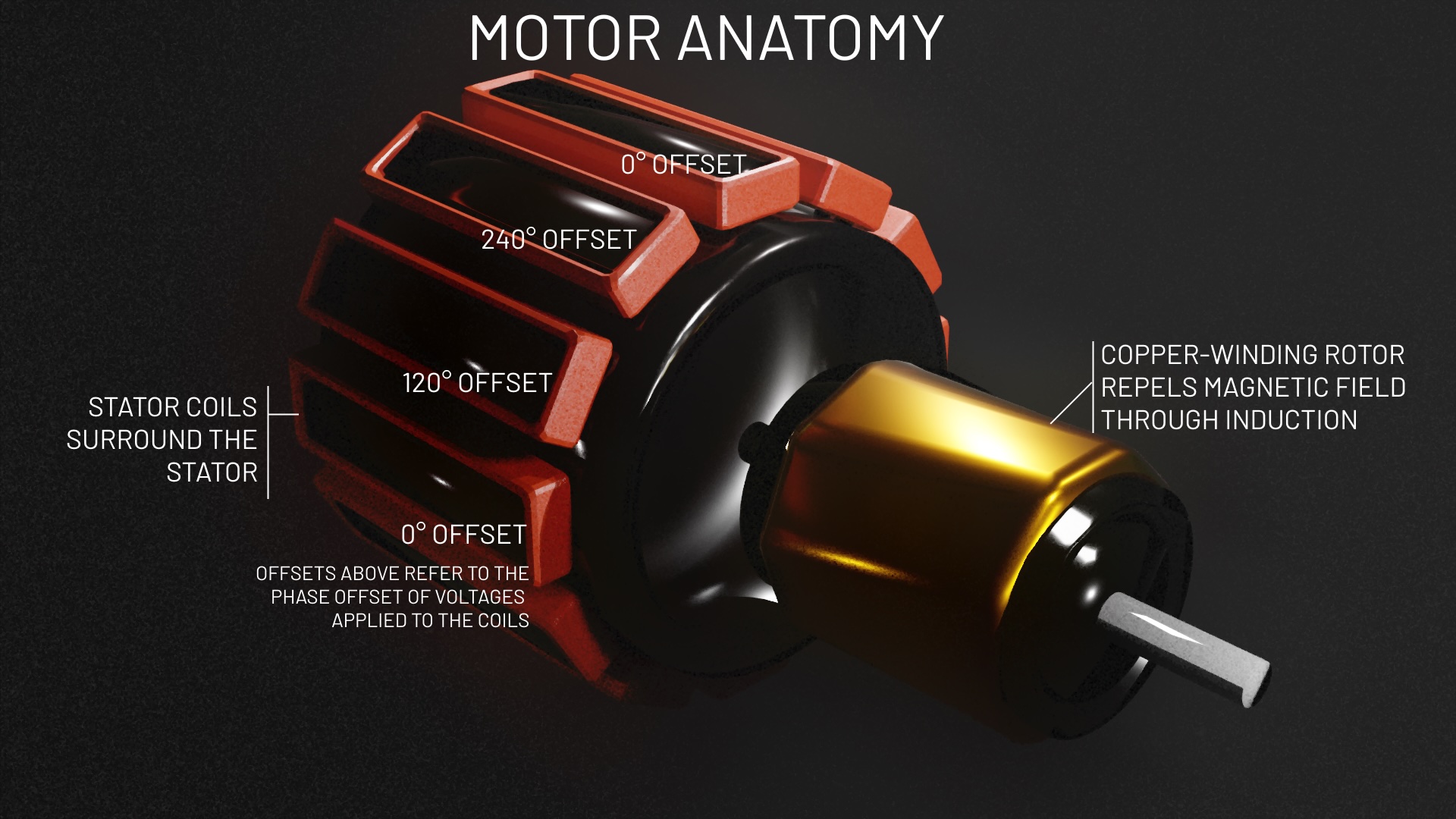

The engine in an electric car is typically an induction permanent-magnet brushless three-phase four-pole AC motor. The "crankshaft" is the motor's rotor, which is a metal cylinder. It can be constructed with many neodymium magnets (non-induction motors) or copper windings (induction motors). The rotor spins freely; there are no brushes in this motor, unlike most motors in home appliances.

The stator is an assembly of a cast-iron core and many copper coils. Three wires, one for each phase, form them. Coils from different wires are positioned next to each other in the stator. The following sequence of numbers is the general pattern in degrees:0-120-240-0-120-240. There are typically 12 coils in a four-pole motor in total and 4 for each phase wrapped around the stator.

THE FUEL

When high-voltage electricity passes through a coil, it generates an electromagnetic field. Nearby pieces of metal will siphon some of the coil's power and produce their own electromagnetic field, pushing away from the active coil. This principle is called induction.

If you have many coils around a hunk of metal, where some are providing current and others are draining, you can push and pull the rotor around in a circle. And with three phases, we can change which areas are pushing and pulling all around the stator. That is the general working principle of a three-phased induction AC motor.

All three phases need to be connected and controlled to make the motor work. You need specialized circuitry to do this. THE BRAINS How does a car, which has a DC battery, generate three-phase AC power? The circuit that controls the motor is called an inverter. It's pretty simple: each phase connects to the battery with transistors. Transistors are solid-state switches, triggered with electricity, that can continuously adjust the amount of current flowing into a circuit.

There are two transistors per phase wire: one for pushing current into the coils, connected to the battery's negative terminal (positive voltage), and one for pulling current (negative voltage), connected to the positive terminal (No, not a measly 12-volt battery. The battery Tesla uses takes up the entire underside of the car!). Only one transistor is on at a time, allowing us to produce a nice sine wave for each phase.

A computer varies the amount of current going to the motor with each transistor. It can change the speed by cycling each phase faster, and it can change power by making them supply more current.

Note that because computers are digital, the transistors are technically not continuously variable. Instead, the computer sends pulses to each transistor of varying lengths to change the amount of power to each coil.

COOLING AND CHARGING

The battery and motor do get hot while driving, so there is a cooling system onboard, just like any other car. Because the motor can spin so fast, you don't need a transmission, so it directly connects to the differential, which supplies power to the wheels.

The circuits that charge the battery are in the car (In the Tesla Model S, under the back seat). They convert the power from a wall socket or fast charger into high-voltage electricity for the battery and supply the current to the battery's terminals to charge it.

This article is a summary of the mechanical components of an electric car. I will probably do more articles about self-driving technologies and battery technology, but until then, peace.