How I Fixed My Truck

Andy Grace

Published 2020-10-27T00:00:00Z

I love my truck. My parents bought a '96 Toyota Tacoma a few years ago after our '93 T-100 started experiencing severe rust. It's different from the Chevy's and Fords around here that you see people around here drive: this thing has a soul, and despite having just 150 horsepower, you can't help but grin as you pass the idiots that go 30 in a 55. It almost mocks you when you go slow, saying, "I can go faster than this. Find the accelerator pedal, grandpa."

However, a year and a half ago, the truck had a problem. I was coming home from a grad party, going 50 down a backroad. The truck bucked and flickered the check engine light. I didn't think much of it, but the truck did it again as I passed someone on a different trip to the optometrist. Except it wasn't just a buck: it was a complete power loss that didn't shake until I was in the parking lot. I went from 150 strong steeds to 70 diseased shetland ponies in about a hundredth of a second.

Fortunately, the auto parts next door had a scanner I could use, but nothing popped up, despite the check engine light being on when they went to plug in the scanner. And I don't mean no codes showed up: I mean no computer showed up. Something was messed up underneath the dash. Whether it was a wire, faulty sensor interfering with the computer, or the computer itself remained a mystery.

Car (Computer) Talk

In case you don't know, most cars are computers on wheels. Cars since the '80s use a computer (or many) to figure out what ratio of oxygen to fuel they should burn, control spark voltage, valve timing, fuel injectors, etc. There are other modules for controlling other functions like ABS and the airbag system (SRS). The main one is typically called the ECM. My truck has an ECM and an airbag controller. Modern cars might have dozens of computers and microcontrollers: perhaps there's one for the motor, one for the gas pedal, one for traction control, one for locks and windows, etc. Electric cars are even more complicated - the average Tesla has a computer for the infotainment system, dashboard, motor, charger, battery system... etc.

Before 1996, each automaker had a different way of sending data through a vehicle. But then the government required that each car have a diagnostic port. So the automakers adopted CAN (controller area network) busses to like the computers; think ethernet in a car, minus routers. Every device takes turns sending data, which makes CAN possible. If transmissions collide, then the least-prioritized device will stop sending data, and devices can usually recover the data.

The diagnostic port uses CAN protocols that cars use to this day. This port is hidden in your vehicle (typically in the driver's footwell or next to the fusebox) and can give you all the information you want about a car, because it's connected to all the sensors and computers. Electric vehicles might omit some readings and lack some components (such as O2 sensor readings and Mass Air Flow sensor readings); however, a Tesla still gives you access to motor statistics and the engine computer (It's not the touchscreen. The engine computer, in this case, is next to the motor).

Let's move away from educational content and back to the story: We got the truck to my mechanic. However, because the truck was losing power randomly and intermittently, he couldn't find anything wrong with it. Whenever it lost power, I would go to the shop, but after it sat in the lot for an hour or so, it wouldn't show any symptoms. After a few trips where the truck stopped acting up in the parking lot, I kept the ignition on and showed my mechanic that something was wrong. My mechanic tried replacing the usual suspects (O2, mass airflow sensor, distributor cap, etc.), but nothing worked. He didn't want to admit it was the wiring, because that's a pain to replace. But without any other options, he pulled apart the dash, replaced harnesses, and checked for fretting (oxidized connectors). After six months, we finally had the truck back, symptom-free. Life was good...

Until it started doing the exact same thing this August. It was running oddly before; I thought the idle was weird, and there were minor shakes where the truck didn't turn on the check engine light. But then it got undrivable. It wouldn't even go to the gas station, a mere 6 miles from my house, without messing up. And in a rural area where groceries are 30 minutes away, that's not acceptable.

I tried the mechanic again. But once again, the truck was the worst patient, almost like a guy that had random intermittent strokes without any apparent cause. And we were once again taking the truck over to his shop, unable to find the cause of unexpected power loss.

And around two weeks ago, I was watching The 8-Bit Guy on YouTube. He's a content creator that explains how retro technology works and frequently restores old computers and teaches you a lot about tech in the process. He was repairing a Macintosh LC, a computer that's around 25 years old. It had capacitors (tiny charge-storing components that filter signals) leaking corrosive electrolyte on the board. That caused a speaker to make random, intermittent squeals.

Random.

Intermittent.

Holy sh#t. The problem wasn't the wiring, nor the sensors. It was the computer in the truck. Some capacitor probably checked out. My truck needed brain surgery. I called up the mechanic, but he was busy in Maryland, helping a relative move.

Redneck Engineering Begins

At that point, I figured I was $300 to $1000 in the hole. Even though the computers in a car are thousands of times less powerful than my gaming rig, they're designed to work in challenging conditions and have hardened components, so they cost a lot of money to replace. But I looked up the capacitors, which only cost around $1 each. I figured that once I buy a soldering iron and materials, $1040 isn't that much of a difference from $1000, so I might as well try to repair the computer before I buy a new one.

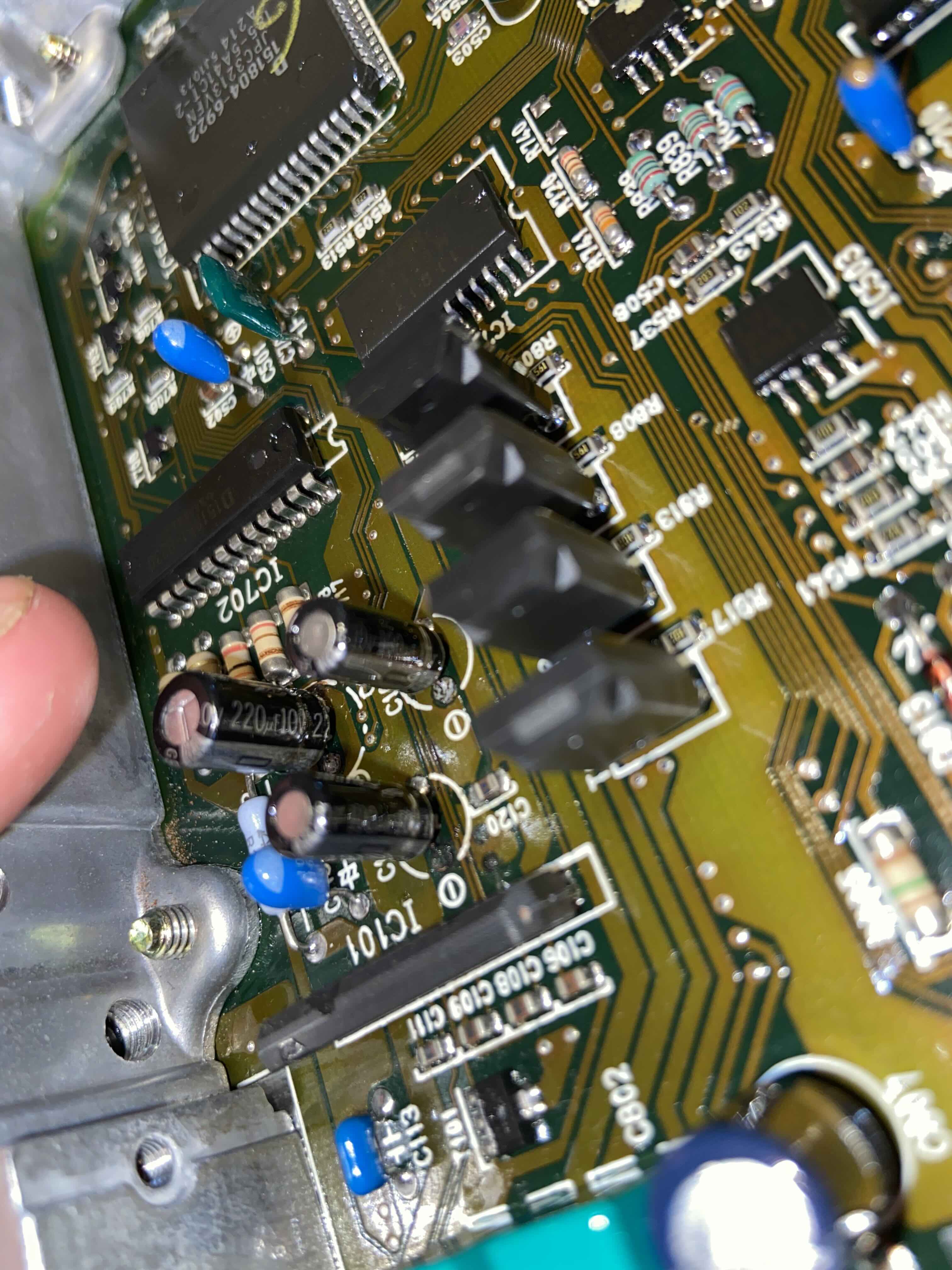

I downloaded the service manual and got to work. I pulled out the glovebox and fascia behind the dash, disconnected three connectors, and voila: there was the ECM. I pulled it out, opened it up (thank God it had Phillip's head screws. Newer ones likely have Torx security bits and lots of adhesive), and BAM: one capacitor with white leads, and one with brown, disintegrated ones.

A few days later, I bought a soldering iron, solder, and some solder-sucking wire to soak up the solder holding the old caps in. I put a towel on the kitchen table, cracked open the ECM, and proceeded with brain surgery, not knowing how to solder but knowing that if this was the solution, I would have saved lots of money and I'd have a functioning truck.

After around two hours of discovering how to solder and accidentally soldering a needle to the board, I got the first one out and put the new one in. The next one came out a lot easier, but I struggled with the leads for around 20 minutes on that one. But I got them out, put the new capacitor in, put it back together, prayed that I didn't inhale too much lead, and went outside.

I plugged in the computer, reconnected the battery, and expected something to burn, but nothing did. I turned the key, and the truck roared to life, no longer ill and suffering aneurisms every 5 minutes. I was cautious, but I was wearing a grin, happy that I pulled off something that most people wouldn't dare do to their cars.

And a week later, it's running like a top. The power loss hasn't plagued me again yet. The truck is once again eager to sprint and smoke Fiat products in longevity and performance. It's just something cool (well, nerdy) that I did to fix my truck. I'm not responsible if you have similar symptoms and end up destroying your car, but sometimes you should take a chance and fix the car. If you figure out why things work, you save money, get smarter, and know enough not to buy the glorified Fiat 500s rebadged as RAM trucks.